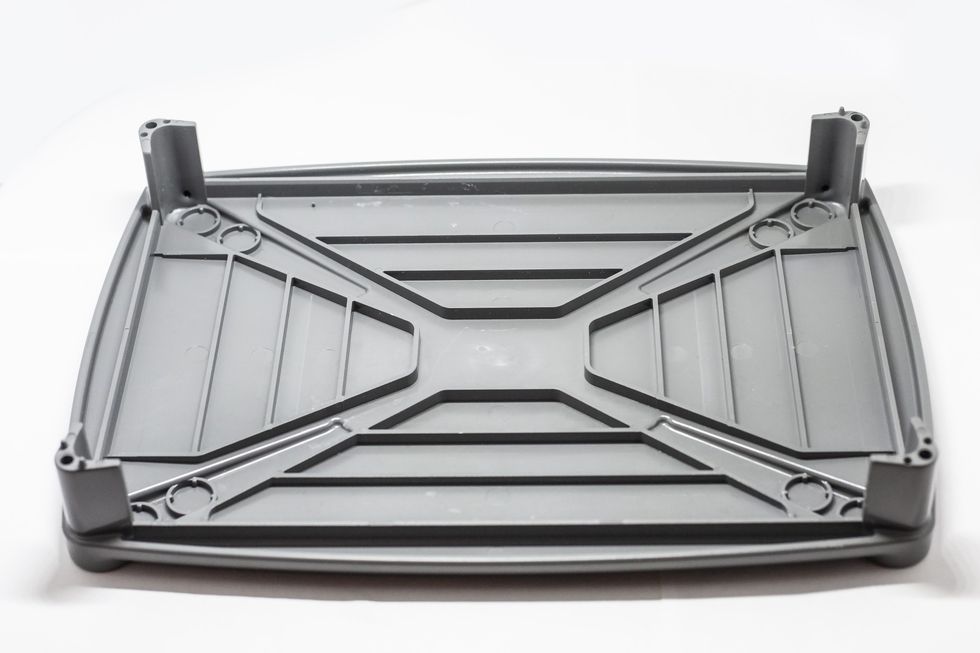

Parts made of plastics are gaining ground in an increasingly wide range of industries around the world, including automotive, military technology, aviation, medical technology, industrial electronics and household appliances. As a result of the dynamic development of the plastics industry, a growing number of parts can now be replaced by plastics. This even includes parts that would have previously been unimaginable and could only be produced using other traditional materials such as metals.

The biggest advantage of injection moulding is that other technologies would not be capable of manufacturing products with complex geometries or small sizes in a more efficient way. The flexibility of the technology allows for the economical production of a large number of products with the same geometric and mechanical properties.

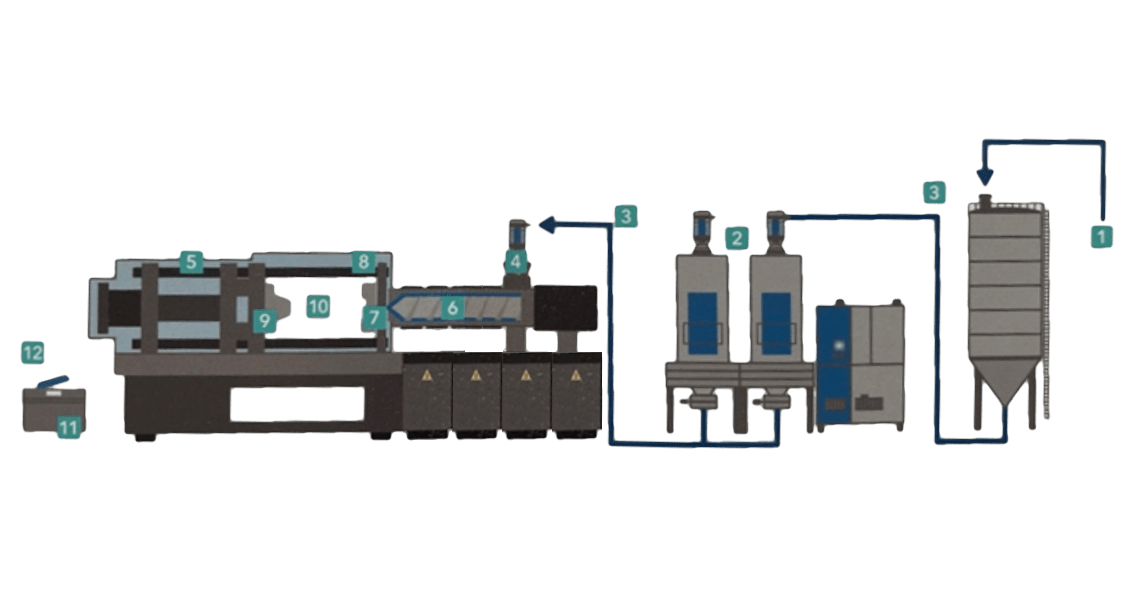

The injection moulding process in brief:

Prior to processing, plastic pellets are prepared for the injection moulding process depending on whether they require drying or not. The material is dried at a specific temperature according to its specifications for the appropriate time to remove the moisture absorbed from the environment. The properly prepared material is brought to the injection moulding machine by a material conveyance system. Solid pellets melt due to heat and shearing and are delivered by the screw in the injection moulding machine into the mould cavity where it solidifies into its final form.

| 1 | Material preparation |

| 2 | Drying system |

| 3 | Material conveyance |

| 4 | Conveyor |

| 5 | Clamping unit |

| 6 | Injector unit |

| 7,9 | Clamping unit |

| 8 | Packing |

| 10 | Mould opening |

| 11,12 | Sorting, packaging |