Moulding with thermosets

When using thermoset processing technology, we inject the thermoset to be processed into a heated mould where it melts due to the heat and then, with the constant application of heat, it becomes cross-linked and is shaped into its final form.

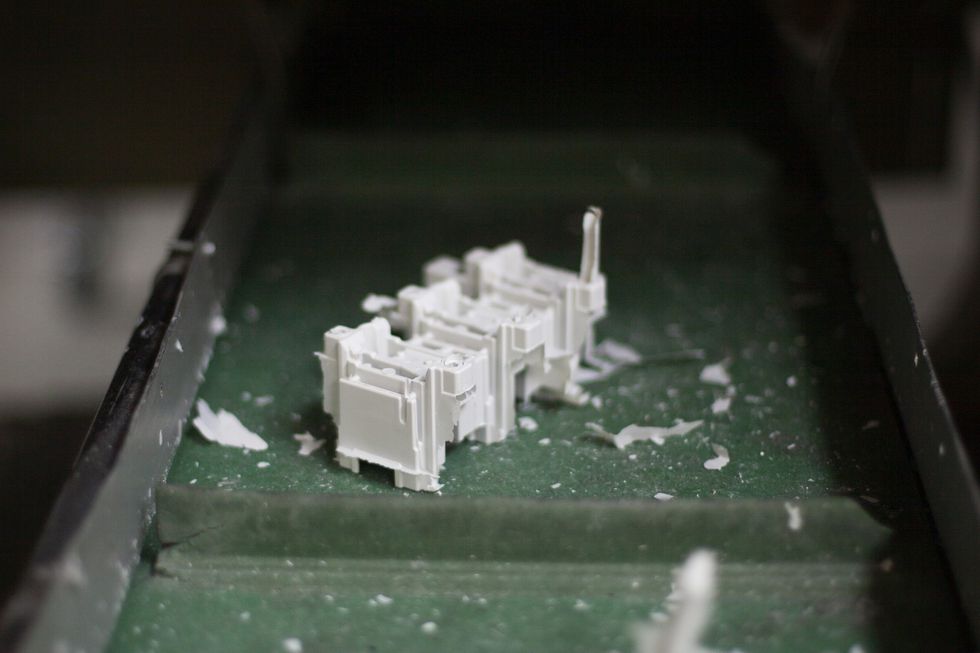

When the mould is opened, the finished product is removed from the cavity by the ejection system and is either placed on a conveyor or, if needed, picked up by a robot to perform other operations to shape the product into its final form.

What gives our company an edge over our competition on the market is that in addition to conventional injection moulding, we also apply special injection moulding technologies, targeting niches that require higher added value and specific technologies. These technologies include multi-component injection moulding, overmoulding, injection moulding of thin-walled products and thermoset moulding from both moist polyester and resin-based materials.