Machine fleet

Our company’s machine fleet is divided into three categories.

- Conventional one-component thermoplastic injection moulding machines

- Two-component thermoplastic injection moulding machines

- Thermoset injection moulding machines (BMC, SMC, resin)

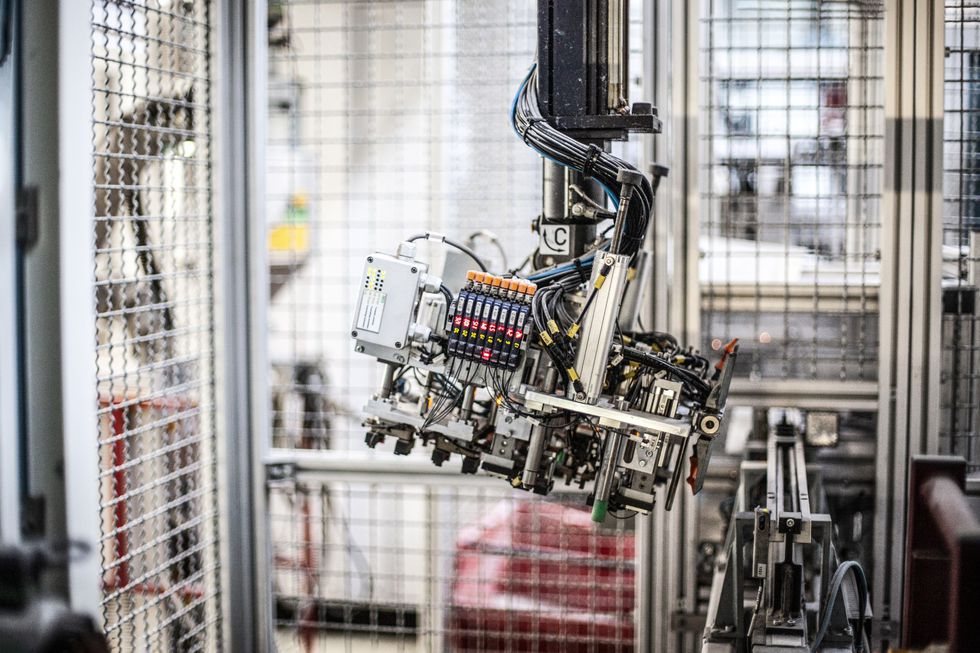

Our conventional one-component injection moulding machines are available with clamping forces ranging from 40 to 300 tons. Equipped with state-of-the-art controls, our machines are made by the most renowned machine manufacturers in Europe (Arburg, Engel, Wittmann-Battenfeld, KraussMaffei). The average age of our machines is 8 years. To ensure the stability of the manufacturing process and improve productivity, the majority of the machines are equipped with sprue pickers or three-axis precision robots. We have 9 of this type of machine available.

All of our two-component thermoplastic injection moulding machines are made by Wittmann-Battenfeld. Every machine is equipped with a three-axis precision robot to ensure productivity. We have three of this type of machine, each with a clamping force of 110 tons.

Thermoset injection moulding machines are divided into two broad categories based on the material to be processed.

For moist polyester manufacturing, we have two injection moulding machines with clamping forces of 110 and 200 tons. Both machines are equipped with three-axis precision robots.

For resin-based (epoxy, melamine) manufacturing, we have a machine with 60 tons of clamping force.